Related Research Paper

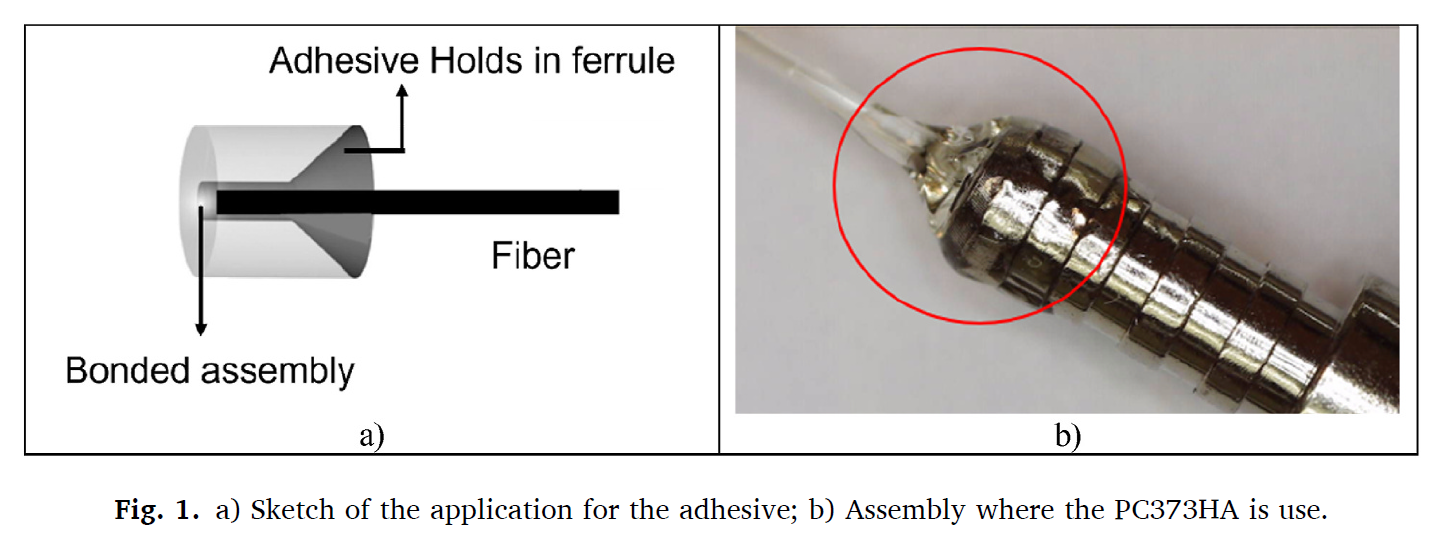

In some laser assemblies, optical components are glued on their metal mount using a photo cross linkable adhesive. All these components are submitted to medium to high temperatures for several hours upon laser’s operation time. The subsequent thermal stresses endured by the adhesive could lead to its degradation, alter thus the functioning of the assembly and impact the alignment of the laser, key issues in laser applications. This work focuses on the investigation and the modeling of the lifespan, the degradation in the face of thermal stresses, particularly those generated by a laser, and of the ageing of a photo cross linkable adhesive, PC373HA. The thermal characterization is performed using Thermo Gravimetric Analysis and allows for the development, the validation and the comparison of three models based on Arrhenius’ law to estimate the lifetime of adhesives as a function of temperature. A temperature of 150◦C is identified as a threshold to ensure limited degradation over the 15 h requested for laser operation endurances. The Ozawa-Flynn-Wall model and the Kissinger-Akahira-Sunose model correctly reproduce PC373HA’s thermal behavior submitted to different thermal scenarii (temperatures, heating rates …). Both show that the higher the temperature, the faster the degradation process, approximately 10 min at 220 ◦C and 100 min at 180 ◦C, much less than the required 15 h. Besides, in the event of an incident with the laser, if the temperature exceeds 200 ◦C for more than 10 min or 180 ◦C for more than 100 min, corrective action should be taken, and the adhesive should be replaced. These models therefore provide fundamental information for laser applications and will allow the implementation of preventive solutions during use but also in case of incident.

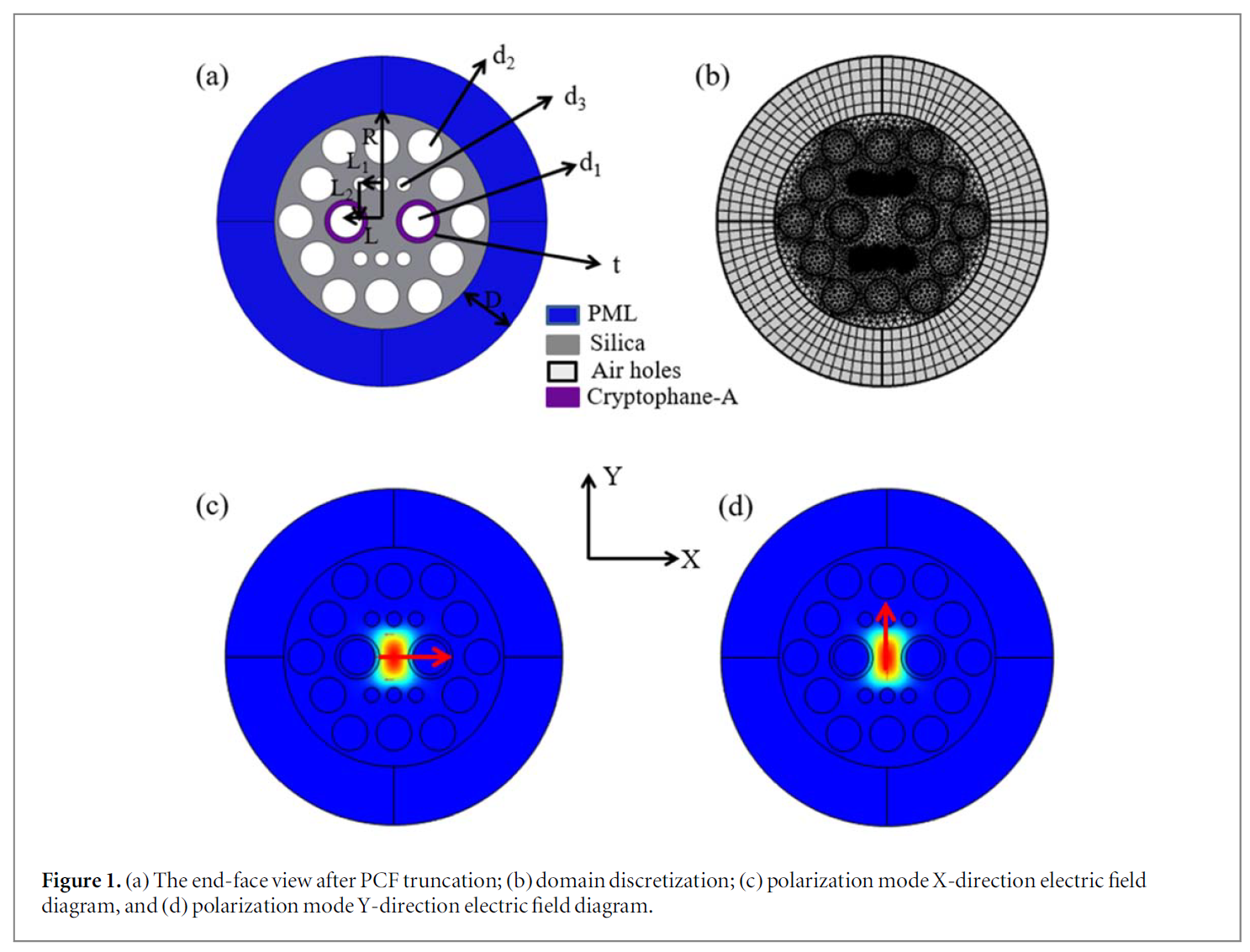

Methane gas, due to its high flammability, is convenient for people’s daily lives, but its flammability poses safety hazards. Methane tends to explode when mixed with air. Therefore, it is particularly important to be able to effectively detect methane gas concentrations. A new methane gas sensor is presented in this paper. It is extremely sensitive to the reaction of methane gas. It consists of two fiber Sagnac interferometer (SI) loops, which utilize the vernier effect. The two fiber SI loops remain parallel. The optical fiber structure of the effective sensing in the sensing SI loop and the effective sensing in the reference SI loop are the same. Both of them adopt the polarization-maintaining photonic crystal fiber (PM-PCF) designed in this paper. However, the sensing SI loop uses a two-step filling technique to block small air holes and an immersion technique to deposit methane gas sensitive film on large air holes in PM-PCF. The sensing capability of the methane gas sensor was evaluated utilizing the finite element method (FEM). The numerical simulation results show that under the condition of the concentration of methane gas in the environment is 0–3.5%, the average sensitivity of two parallel Sagnac loops is 260.86nm/%. Compared with other fiber optic methane gas sensors, the sensitivity of the sensor designed by this scheme is significantly improved, which provides a valuable reference and direction for the development of new methods and the design of ultra-sensitive methane gas sensors.

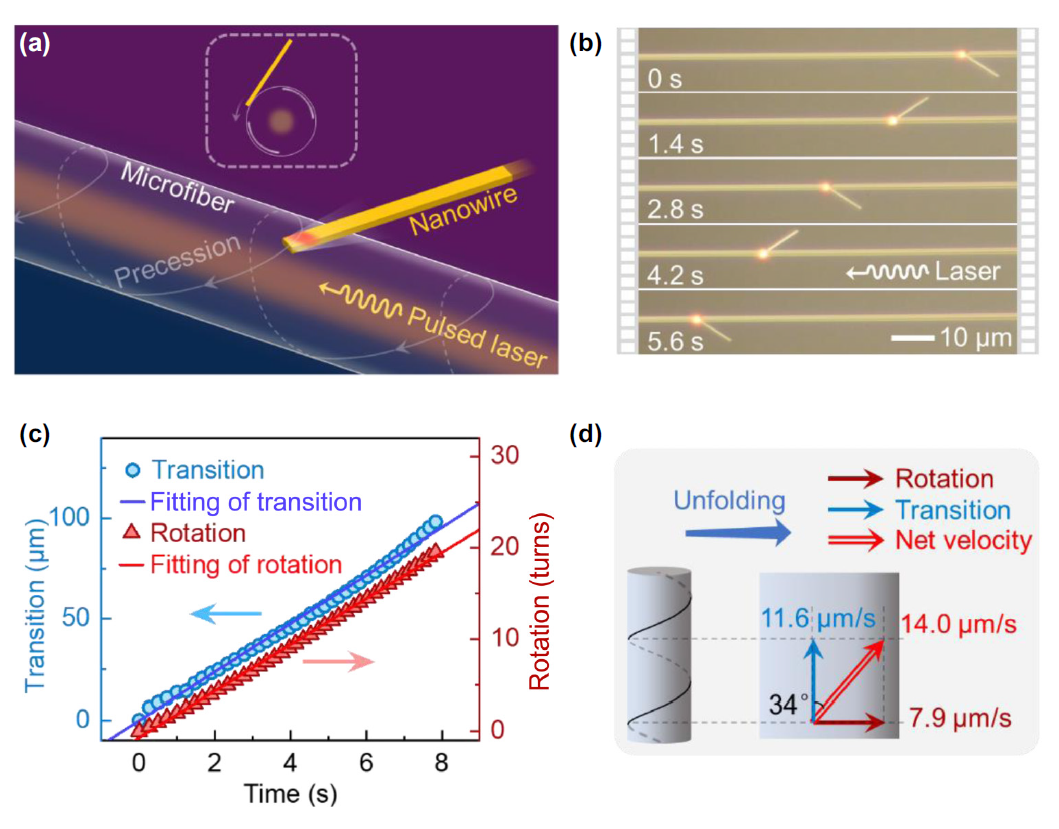

With the development of nanotechnology, there has been great interest in manipulating nanomaterials. However, the development of manipulating techniques still faces challenges and is slower than that of nanomaterial fabrication techniques. The key to solving this problem is to develop universal nanomotors that can provide energy to overcome the large interfacial resistance caused by the high surface-to-volume ratio at the nanoscale. Photothermal gradient forces generated by photothermal shock have been demonstrated to drive nanomaterials on dry, flat substrates. Yet, the driving mechanism for the motion of semi suspended nanomaterials with a single-point contact remains unclear. In this work, we demonstrate metal nanowire rotation motors that operate on the curved surfaces of silica microfibers. The theoretical analysis proves the unified principle of body and surface forces and confirms that the direct driving power source is the internal stress, a generalized surface force. Experimentally, we achieve pure and stable in situ rotation of single nanowires without axial translation and rotation of multi nanowire assemblies. Our work provides a firm foundation for using transient photothermal gradient forces to manipulate nanomaterials at the nanoscale and broadens the potential applications of nanomotors.

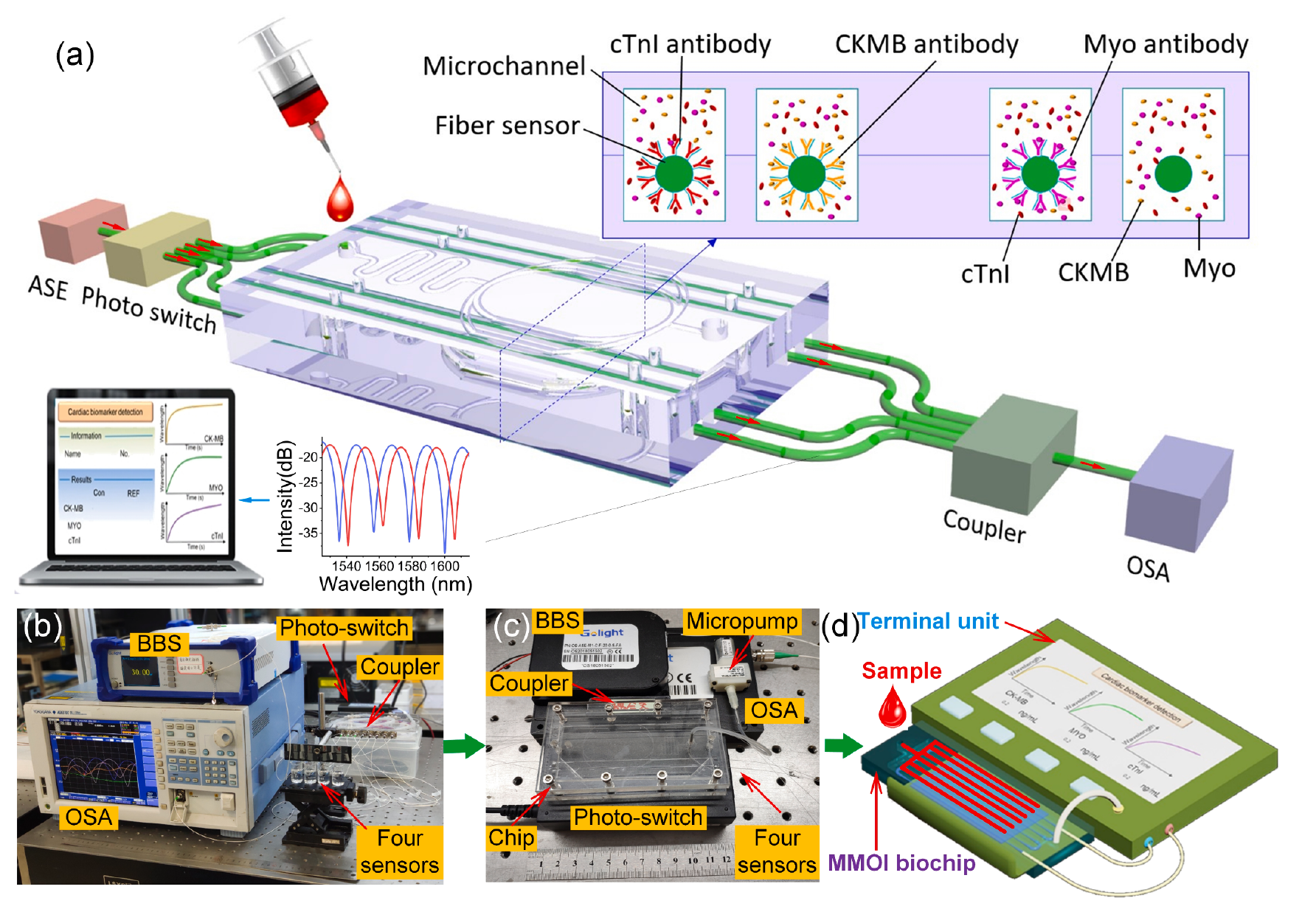

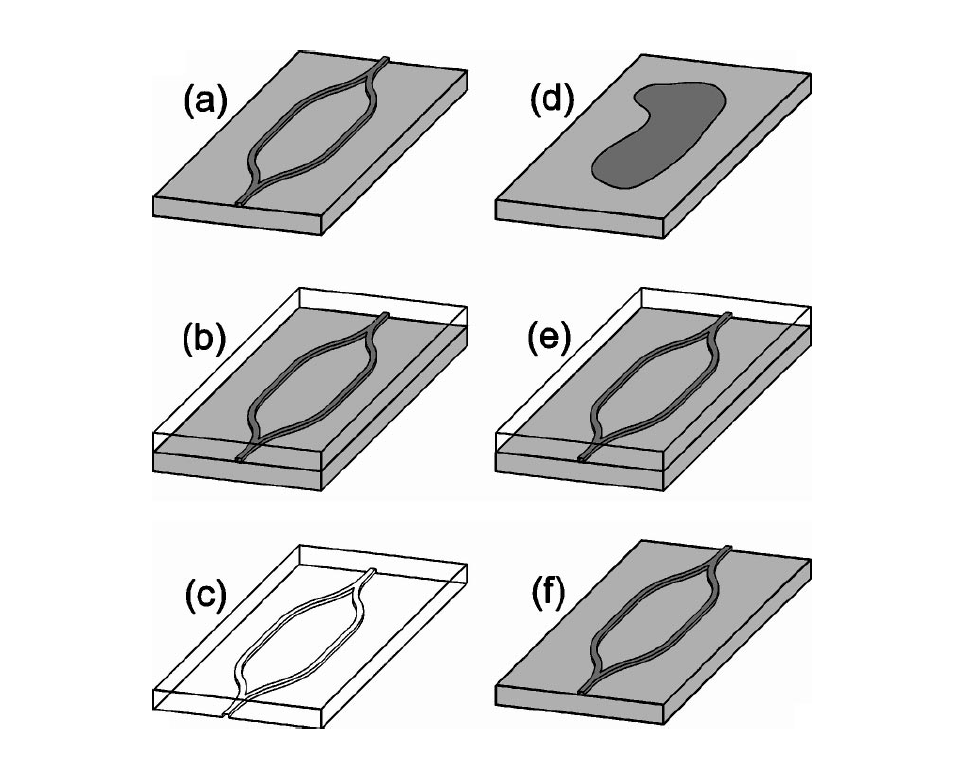

Point-of-care testing (POCT), which enables personalized, accurate, affordable, and accessible medical services, is indispensable in the diagnostics, screening, and treatment of disease, especially for emergency and severe cases. Considering the complexity of disease, multiplexed point-of-care (MPOC) testing is very important for the simultaneous detection of several biomarkers to improve accuracy and increase analysis throughput. In this work, a microfiber interferometer based multiplexed optofluidic (MIMO) chip sensor is proposed for multiplexed, quantitative detection of cardiac biomarkers. Four microfiber interferometers are suspended and fixed in four separate microscale sample channels of an imprinted polydimethylsiloxane (PDMS) chip. A drop of the sample is distributed into the four parallel channels automatically and reacts with the probe on the microfiber sensor surface specifically, which leads to the wavelength shift of the spectrum resulting from evanescent wave interactions with biomolecules. There microfiber interferometers are functionalized with myoglobin (Myo) antibody, cardiac troponin I (cTnI) antibody, and creatine kinase-myocardial band isoenzymes (CK–MB) antibody respectively and the rest microfiber interferometer is with no functionalization, which acts as the control channel to reduce noise. By using compact dedicated commercial optical modules, miniaturized and low cost experimental setup is organized and achieve four channel simultaneous measurement through time division multiplexing. Three cardiac biomarkers, Myo, cTnI, and CK–MB, are synchronously detected on the proposed MIMO chip sensor. In a standard buffer sample, the log-linear sensing range of CK–MB is 0.2 ~ 200 ng/mL with detection limit of 3.7 pg/mL, the log-linear sensing range of Myo is 2 ~ 2000 ng/mL with detection limit of 0.5 ng/mL, and the log-linear sensing range of cTnI 0.02 ~ 20 ng/mL with detection limit of 2.6 pg/mL, which all perfectly cover the actual diagnostic limit of myocardial infarction. Furthermore, the MIMO chip sensor maintains excellent performance of both specificity and detection capabilities in more complex serum samples. In double-blind trials of multiple biomarker detection, the MIMO chip sensor exhibits comparable detection ability with a commercial kit and good resistance to environmental disturbance. The proposed MIMO chip sensor sensing system offers a low-cost, portable, self-driven, and miniaturized scheme for a multiplexed point-of-care testing device, promoting the feasibility and accessibility of personalized medical services and paving the way for clinical application and industrialization.

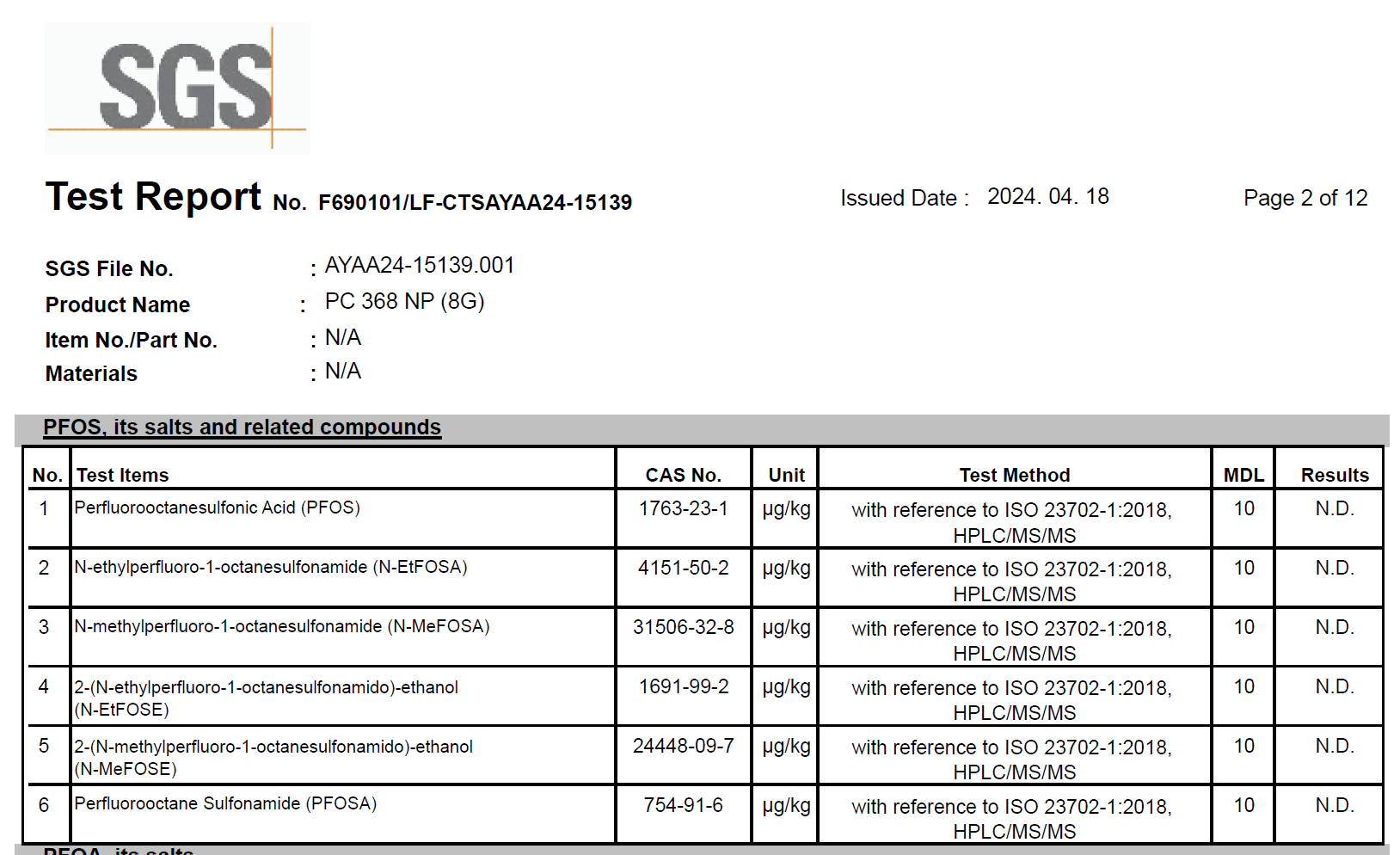

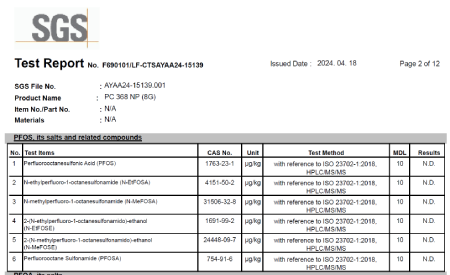

The detection and quantification of 127 known PFAS in PC-368NP is done by 3rd party SGS providing test for a wide range of PFAS compounds using Liquid Chromatography-Mass Spectrometry (LC-MS) for accurate and sensitive detection.The testing was performed with the water-diluted solution (organic dilution solvent) of the submitted sample, and the dilution ratio to water (organic dilution solvent) was one to one thousand. Dilution factor was not applied to the calculation of result values.

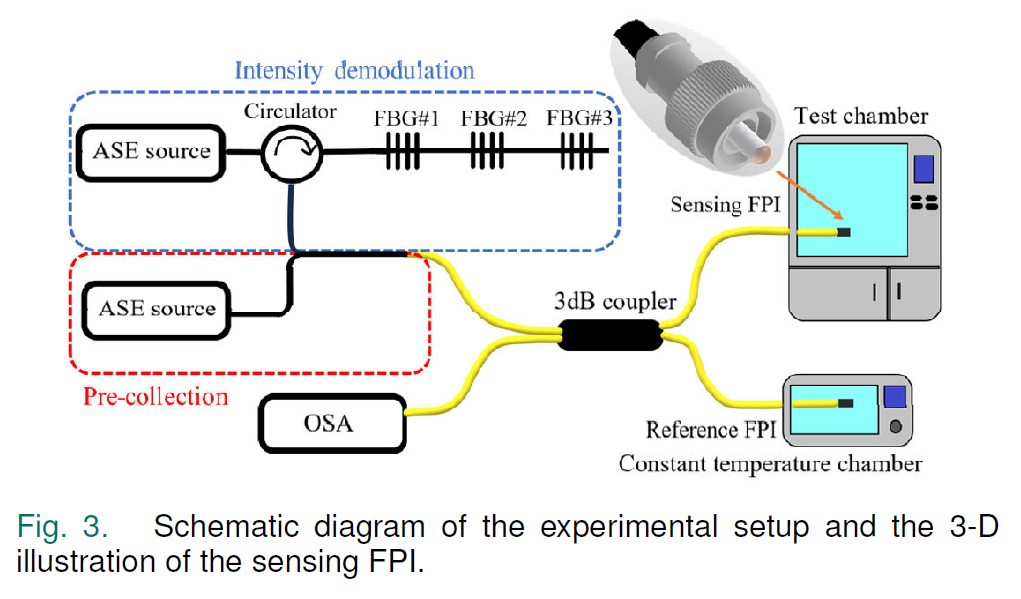

In this article, we introduce an intensity demodulation method for the optical Vernier effect based on an intelligent algorithm. To reduce the requirement for a large number of pre-collected raw spectra for the training of the three-layer neural network, a spectrum interpolation scheme was incorporated. With the proposed method, the measurand can be demodulated by simply measuring the relative intensity at three wavelengths. A Vernier-effect temperature sensor consisting of two parallel fiber Fabry–Perot interferometers (FPIs) was fabricated and used to validate the proposed method. The experimental results demonstrate that the intensity demodulation method yields results in very good agreement with those of conventional spectral demodulation method. The sensor exhibits a sensitivity of 5.82 nm/◦C and a relative error within ±1.23% in the range of 28 ◦C–44 ◦C. The proposed method enables the demodulation system to eliminate the dependence on the expensive optical spectrum analyzer (OSA). This has significant implications for reducing the cost of the optical Vernier-effect demodulation system and facilitating the practical application of such sensors. Index Terms—Demodulation, neural network, optical fiber sensors, Vernier effect.

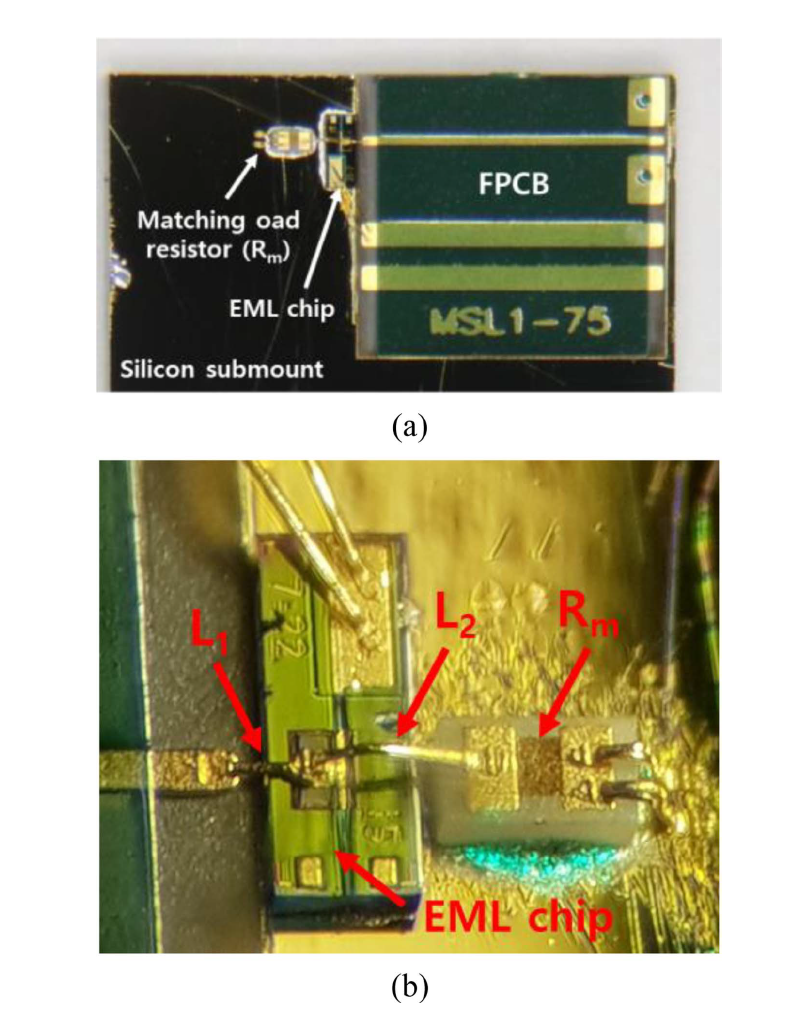

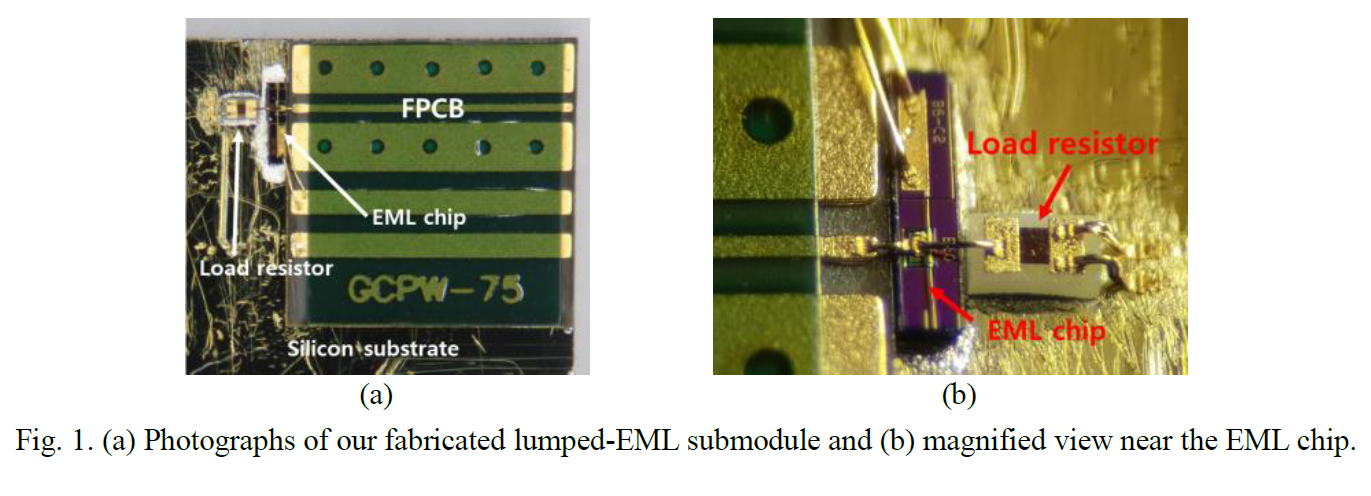

We investigate the influence of a matching load resistance on frequency responses of a lumped-electro-absorption modulator-integrated lasers (EMLs) whose modulation bandwidths are extended by LC resonance effect. An equivalent circuit modeling is performed to determine the optimal values of a matching load resistance enabling 112-Gbaud PAM4 operation for a lumped-EML chip with an electro-absorption modulator (EAM) length of 150 um. To verify the simulation results, we package a lumped-EML submodule and measure its high-frequency characteristics. Then, we experimentally demonstrate that the 3-dB bandwidth of the lumped-EML submodule can be enhanced to 55 GHz and beyond by optimizing the matching load resistance value as well as lengths of the bond wires, although the EAM length is as long as 150 um. The fabricated lumped-EML submodule exhibits clear optical eye patterns under 112-Gbaud PAM4 operation.

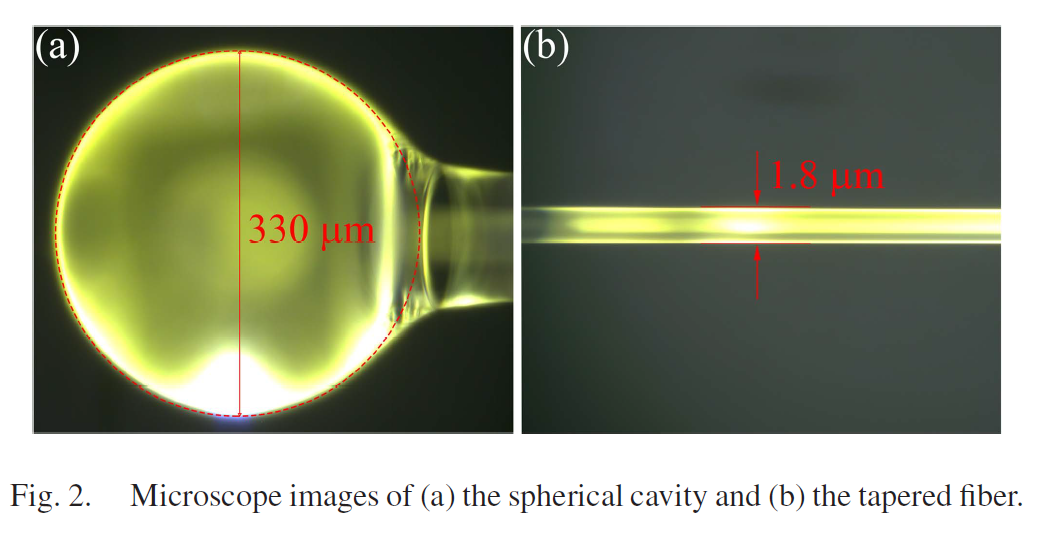

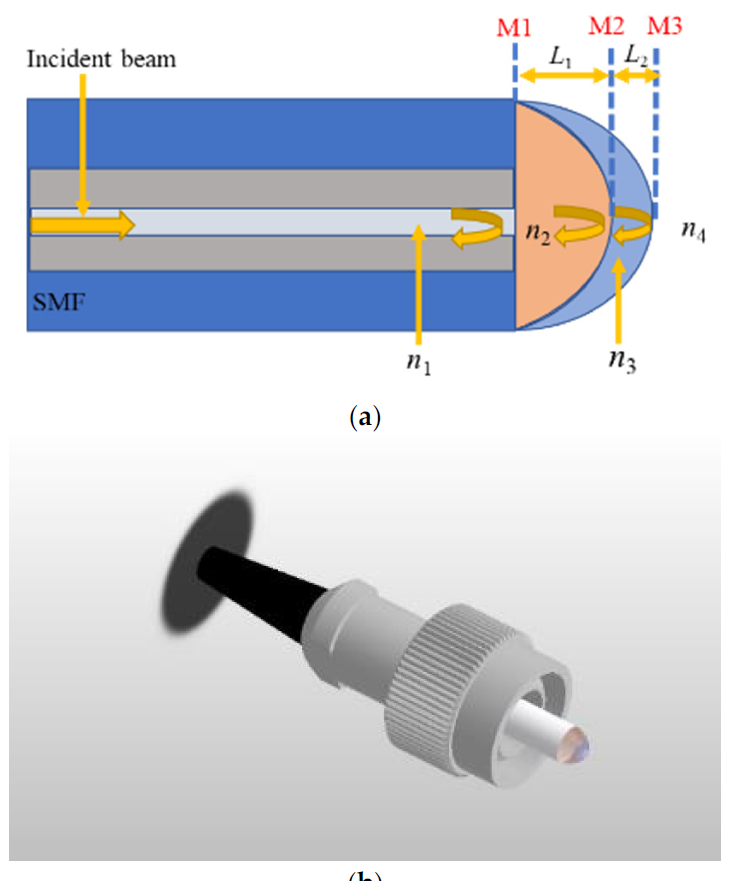

A method for narrowing the linewidth of a DFB laser diode by self-injection locking it to a packaged spherical whispering-gallery-mode (WGM) resonator in add-drop configuration is proposed and experimentally demonstrated. The WGM resonator in add-drop configuration employs a silica microsphere with a diameter of 330 μm as the cavity and two tapered optical fibers with waist diameters of 1.8 μm to excite and collect the WGMs, respectively, by which a passband with a full width at half maximum (FWHM) of 1.47 GHz at the drop port can be achieved. By introducing the resonant feedback into the lasing cavity of the DFB laser diode, the instantaneous linewidth is narrowed by two orders of magnitude, i.e., from116 kHz to 355 Hz. The white noise of the DFB laser diode is suppressed by more than 20 dB for frequencies higher than 10 kHz. In comparison with the weak feedback originating from Rayleigh back scattering in the same spherical WGM resonator, the resonant feedback from the WGM resonator in add-drop configuration is relatively strong, resulting in a higher linewidth narrowing ratio and frequency noise suppression ratio for such a packaged WGM resonator with a moderate quality factor (Q-factor) on the order of 105. The method demonstrated here not only provides an effective solution for narrowing the linewidth of a DFB laser diode but also significantly reduces the stringent requirements on both device fabrication and coupling between the lasing cavity and the external microcavity.

The full realisation of optical fibres in devices such as sensors is reliant on the stability of their polymer coating under in-service conditions. Depending on the application, resistance to several environmental factors may be required, such as high or low humidity level, temperature, pressure, or exposure to aggressive solids, liquids or gases. Changes in mechanical or chemical properties as a result of harsh environments can lead to stresses in the coating and subsequent deterioration of the physical or optical properties of the optical fibre. A variety of coating materials are available on the global market, offering optical fibre manufacturers a plethora of options.

We report on a lumped-EML submodule with 3-dB bandwidths of 68.2 GHz at 25℃ and ~66 GHz at 70℃ using a resistance- optimized LC resonance effect, showing low temperature dependence and making it suitable for 112-Gbaud operation.

In this paper, fiber sensor based on Vernier effect for simultaneous measurement of relative humidity (RH) and temperature is proposed. The sensor is fabricated by coating two kinds of ultraviolet (UV) glue with different refractive indexes (RI) and thicknesses on the end face of a fiber patch cord. The thicknesses of two films are controlled to generate the Vernier effect. The inner film is formed by a cured lower-RI UV glue. The exterior film is formed by a cured higher-RI UV glue, of which thickness is much thinner than the inner film. Through the analysis of the Fast Fourier Transform (FFT) of the reflective spectrum, the Vernier effect is formed by the inner lower-RI polymer cavity and the cavity composed of both polymer films. By calibrating the RH and temperature response of two peaks on the envelope of the reflection spectrum, simultaneous measurements of RH and temperature are realized by solving a set of quadratic equations. Experimental results show that the highest RH and temperature sensitivities of the sensor are 387.3 pm/%RH (in 20%RH to 90%RH) and 533.0 pm/C (in 15 C to 40 C), respectively. The sensor has merits of low cost, simple fabrication, and high sensitivity, which makes it very attractive for applications that need to simultaneously monitor these two parameters.

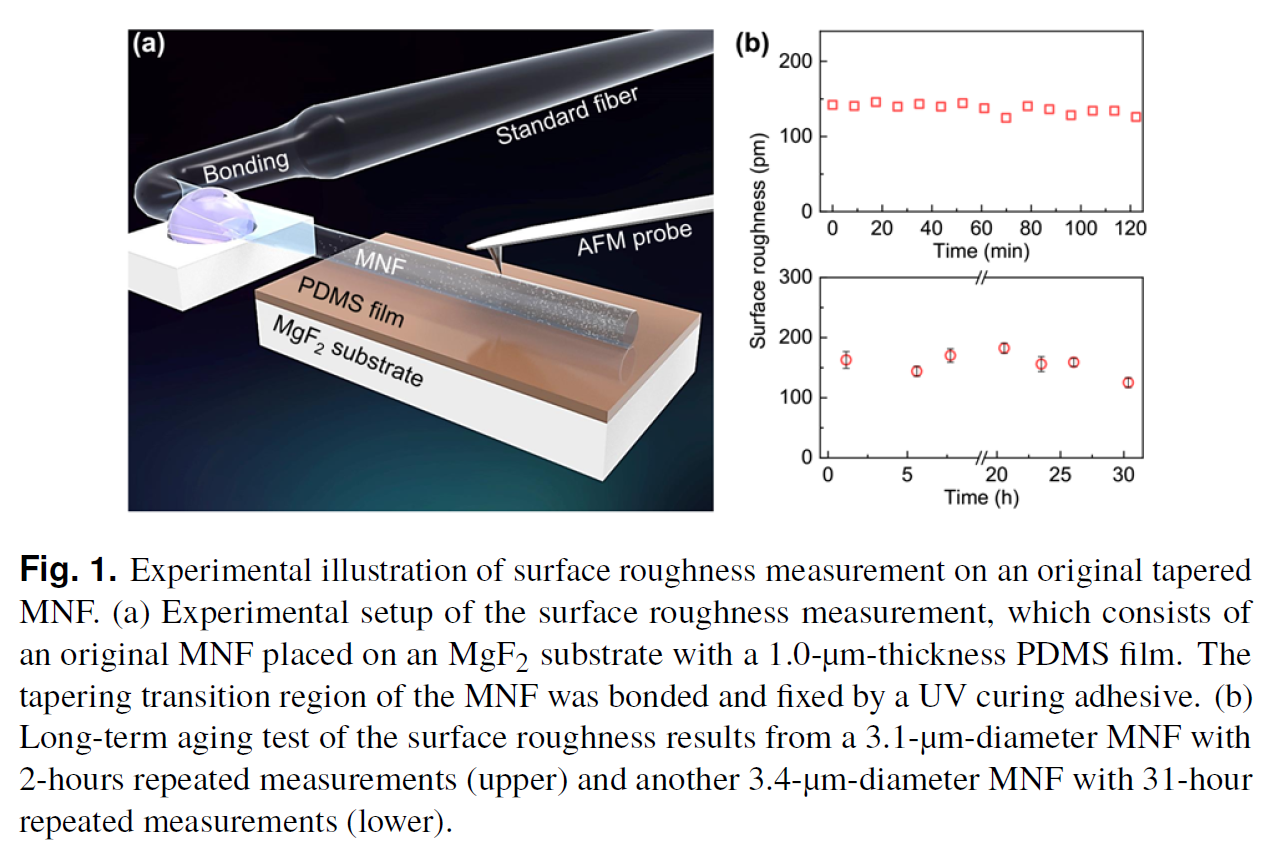

The exploration relevant to the surface changes on optical micro- and nanofibers (MNFs) is still in infancy, and the reported original mechanisms remain long-standing puzzles. Here, by recognizing the combined interactions between fiber heating, mechanically tapering, and high-power pulsed laser guiding processes in MNFs, we establish a general thermal-mechanical photo- activation mechanism that can explain the surface changes on MNFs. Our proposed activation mechanism can be well supported by the systematical experimental results using high intensity nanosecond/femtosecond pulsed lasers. Especially we find large bump-like nanoscale cavities on the fracture ends of thin MNFs. Theoretically, on the basis of greatly increased bond energy activated by the fiber heating and mechanically tapering processes, the energy needed to break the silicon-oxygen bond into dangling bonds is significantly reduced from its intrinsic bandgap of ∼9 eV to as low as ∼4.0 eV, thus high-power pulsed lasers with much smaller photon energy can induce obvious surface changes on MNFs via multi-photon absorption. Finally, we demonstrate that using surfactants can repair the MNF surfaces and exploit them in promising applications ranging from sensing and optoelectronics to nonlinear optics. Our results pave the way for future preventing the performances from degradation and enabling the practical MNF-based device applications.

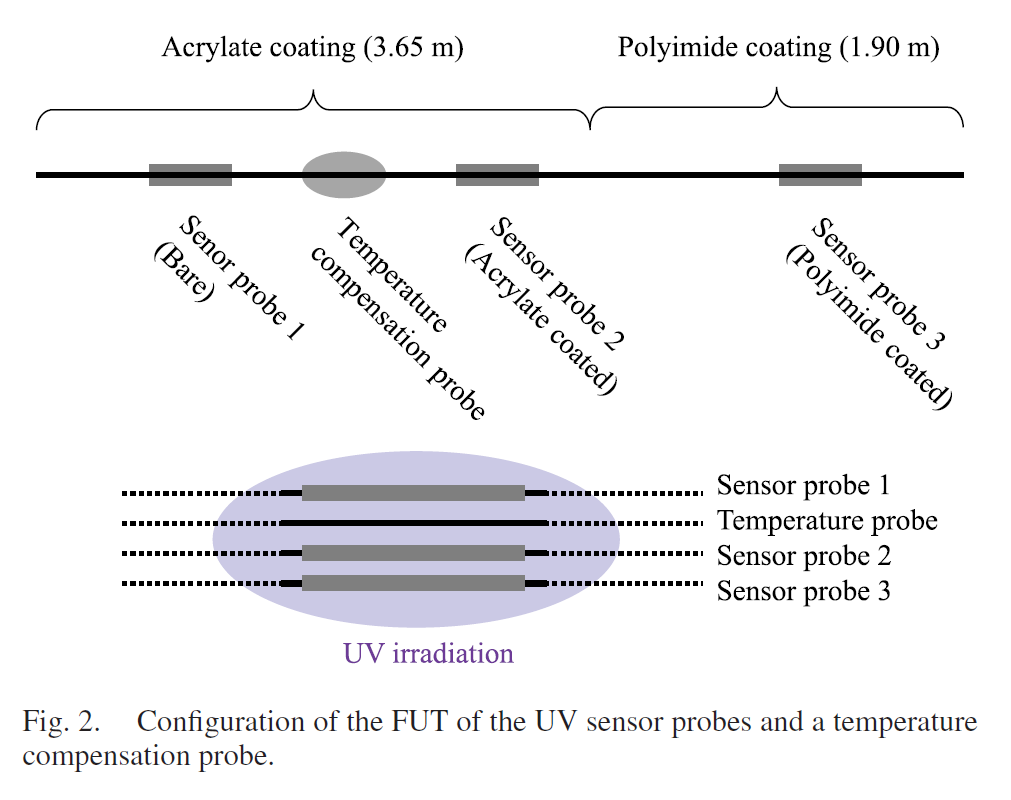

A distributed ultraviolet sensor based on Brillouin scattering in an azobenzene polymer-coated optical fiber is experimentally demonstrated. A Brillouin optical correlation domain analysis applying injection locking and a differential measurement scheme is utilized for the characterization of the extra coating of azobenzene polymer on a single-mode optical fiber with various types of inner coatings. The saturation and relaxation properties of the coated sensor probe are analyzed according to the time and UV intensity. It is demonstrated that the azobenzene coatings on bare and polyimide-coated fiber provide a change in the Brillouin frequency above 70 MHz under UV irradiation of ∼25 mW/cm2 at a wavelength of 365 nm, and the saturation level and saturation time depend on the material of the inner coating and the thickness of the azobenzene coating.

A novel all-optical modulator based on a microfibre coil resonator (MCR) functionalized using MXene is reported. The MCR was manufactured by winding a tapered fibre on a polycarbonate (PC) resin cylinder with low refractive index to support the microfibre, which also forms a fluidic channel coil. The MXene dispersion was injected into the channel to allow the deposition of an MXene layer using a photodeposition process. The transmission spectra were tuned using a tunable laser with a centre wavelength of 1550 nm and the light-matter interaction resulting from the photo-thermal effect and MXene absorption provide the all-optical modulation in this device. The variation of the resonance wavelength, phase shift and extinction ratio of transmission spectrum versus power were determined as 50 pm/mW, 0.262 π/mW and 0.554 dBm/mW respectively. The all-optical modulation properties were further characterized using a lens coupling method and adding a chopper to provide a controlled light source. The rise and fall response times for waveforms of the light signal were 0.179 and 0.145 ms, respectively. The intensity and width of the light signal waveform was modulated using the chopper controlled light source, which indicates that MXene, as a new two-dimensional material, has excellent nonlinear optical effects and the MXene-MCR has the potential for use in ultra-fast optical nonlinear optical processing. The MXene-MCR has several superior characteristics compared with other all-optical modulators including excellent modulation properties, all-fibre construction, easy fabrication and fast response. These advantages demonstrate MXene-MCR has excellent potential for use as a tunable optical filter, an optical switch as well as an all-optical modulator.

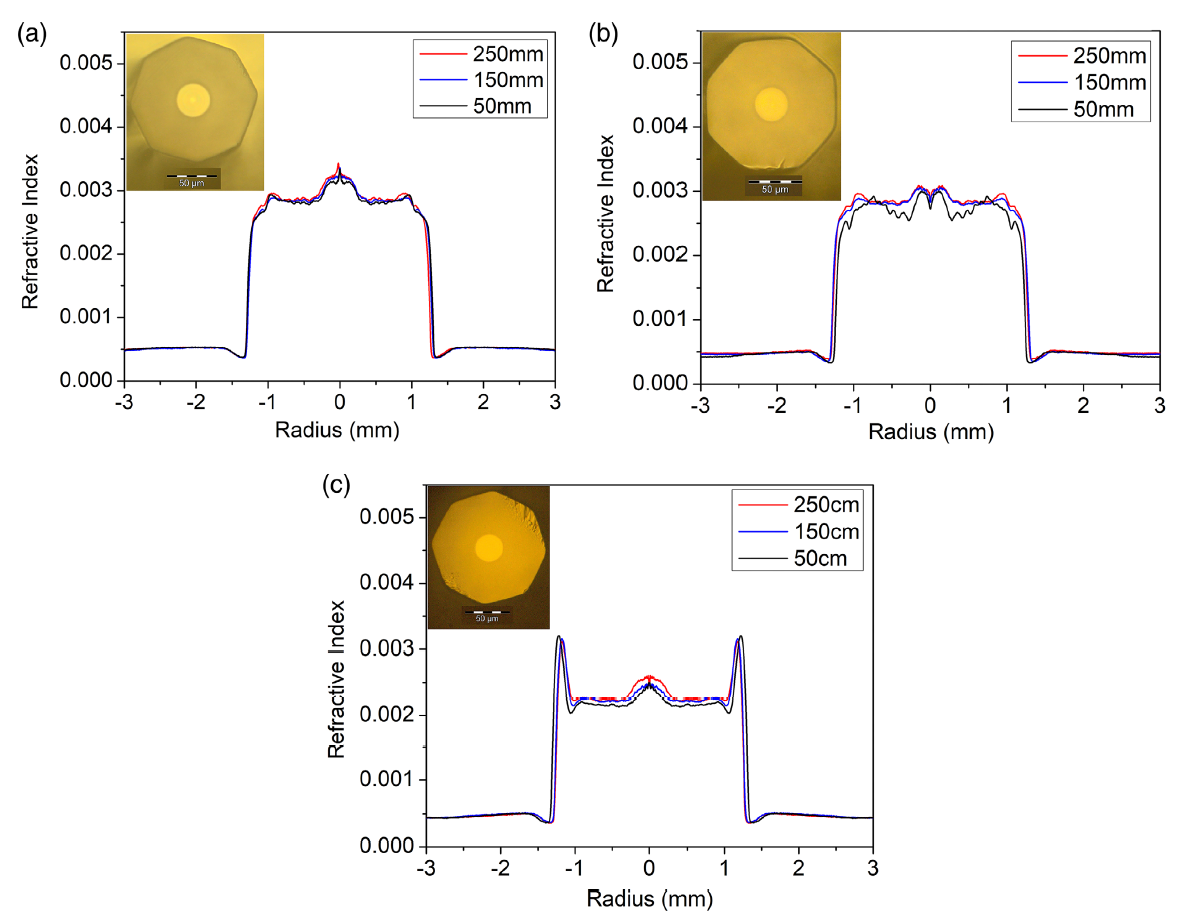

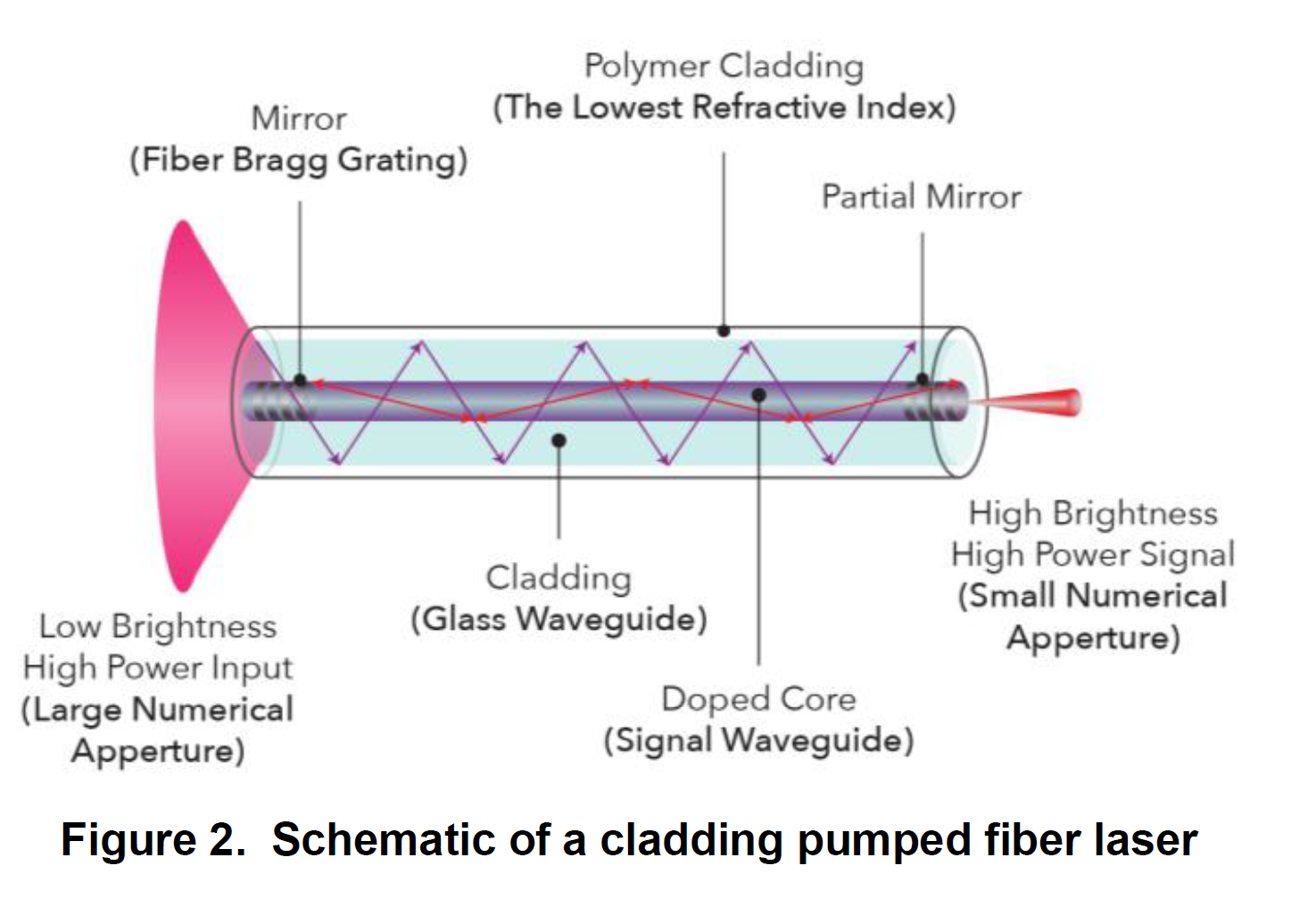

The vapor phase chelate delivery (VPCD) technique in conjunction with the modified chemical vapor deposition (MCVD) process is adopted to fabricate fibers with customized doping profiles. The three large-mode area (LMA) step index fibers with different rare-earth doping profiles in the core region, such as uniform doping, centralized doping, and circumferential doping, are fabricated by optimizing the fabrication parameters. The fibers are tested in a cladding-pumped amplifier configuration and their output beam qualities and signal-to-noise ratio (SNR) are characterized. The investigation reveals that the fiber with centralized doping in the core region exhibits lower M2 compared with the fibers with uniform and circumferential doping, as it has a lower overlap of the higher-order modes with the doped region. The experimental result is further affirmed through theoretically simulated results. The developed fabrication technique shows potential to fabricate specialty fibers of varied designs, where customized doping profiles are required.

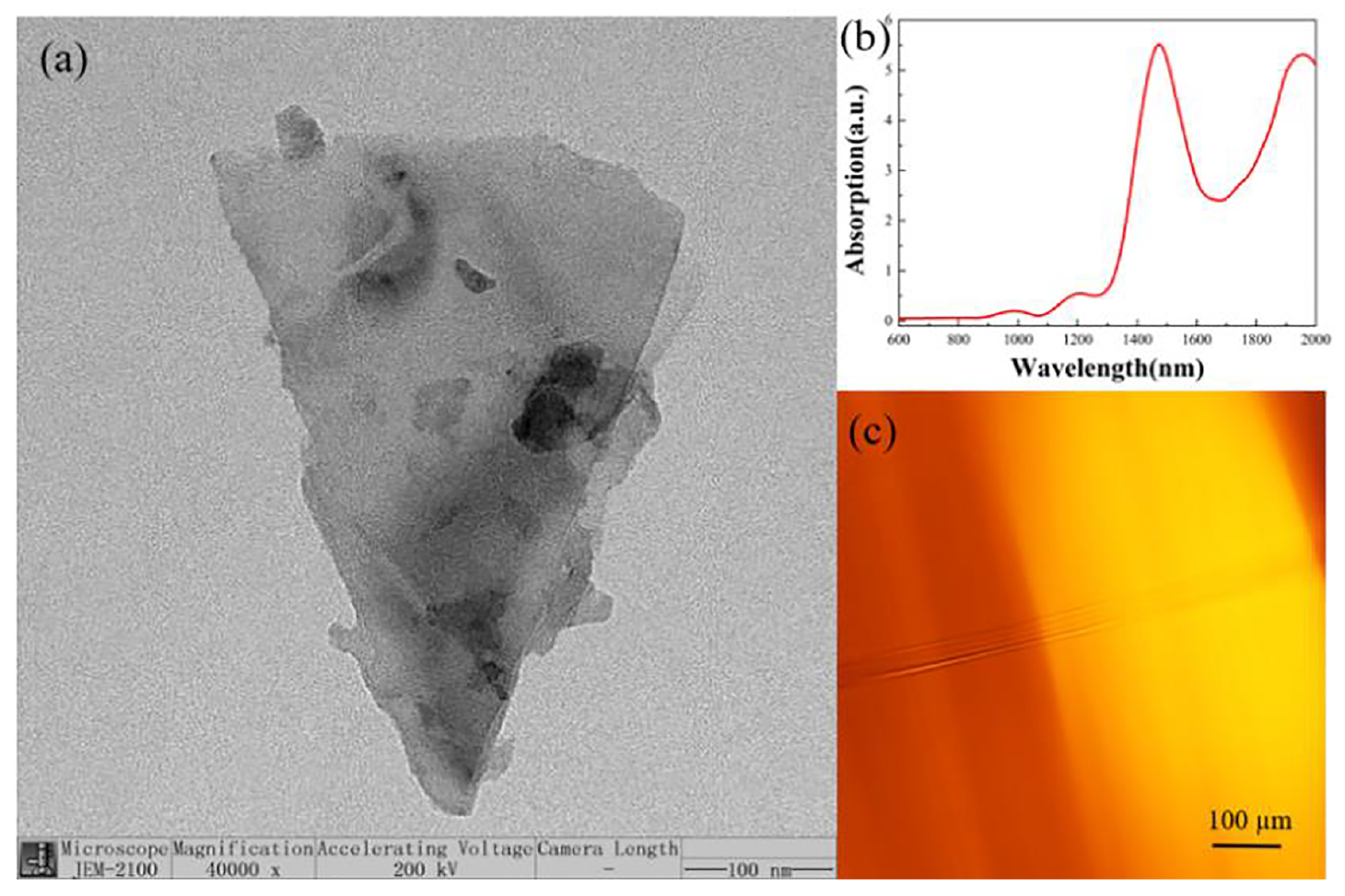

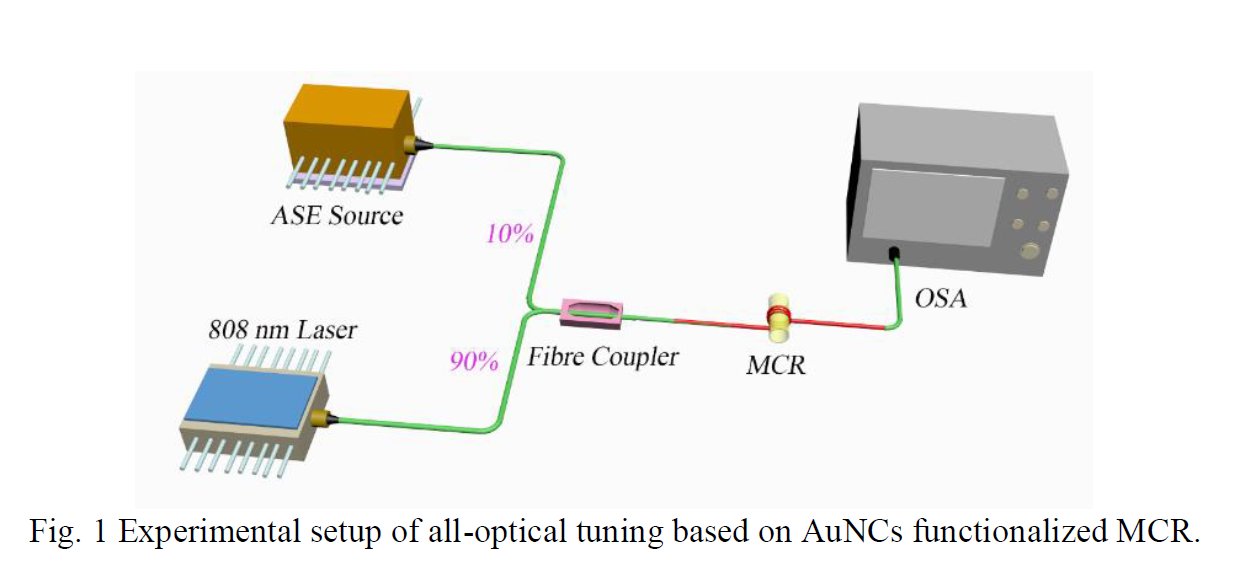

An all-optical tunable microfibre coil resonator (MCR) functionalized using Au nanoclusters (AuNCs) was investigated and demonstrated. The MCR was manufactured by winding tapered fibre on a hollow rod of low refractive index polycarbonate (PC) resin to form a fluidic channel, and the AuNCs aqueous solution was injected into the channel to complete the functionalization process. The resonance wavelength and extinction ratio can be tuned using a pump laser with wavelength of 808 nm due to the photo-thermal effect and photon generated carriers from strong absorption of AuNCs at 808 nm, resulting light-matter interaction and providing all-optical tuning properties, including variations of resonance wavelength and extinction ratio. The variation rate of the resonance wavelength and extinction ratio were determined as 69 pm/mW and 0.459 dBm/mW. The response times of the MCR functionalized with the AuNCs are 11.99 s (rising) and 11.41 s (falling). The AuNCs functionalized MCR has several advantages compared to other tunable resonator devices, including easy fabrication, high tuning efficiency, low cost and all-fibre construction.

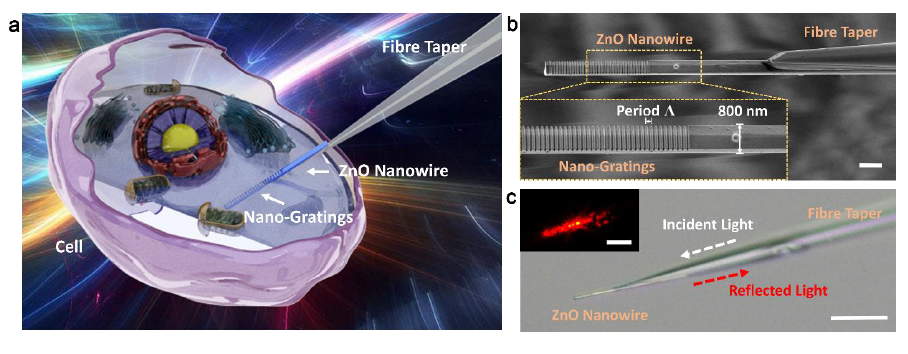

The achievement of all-fibre functional nano-modules for subcellular label-free measurement has long been pursued due to the limitations of manufacturing techniques. In this paper, a compact all-fibre label-free nano-sensor composed of a fibre taper and zinc oxide nano-gratings is designed and applied for the early monitoring of apoptosis in single living cells. Because of its nanoscale dimensions, mechanical flexibility and minimal cytotoxicity to cells, the sensing module can be loaded in cells for long-term in situ tracking with high sensitivity. A gradual increase in the nuclear refractive index during the apoptosis process is observed, revealing the increase in molecular density and the decrease in cell volume. The strategy used in this study not only contributes to the understanding of internal environmental variations during cellular apoptosis but also provides a new platform for non-fluorescent all-fibre devices to investigate cellular events and to promote new progress in fundamental cell biochemical engineering.

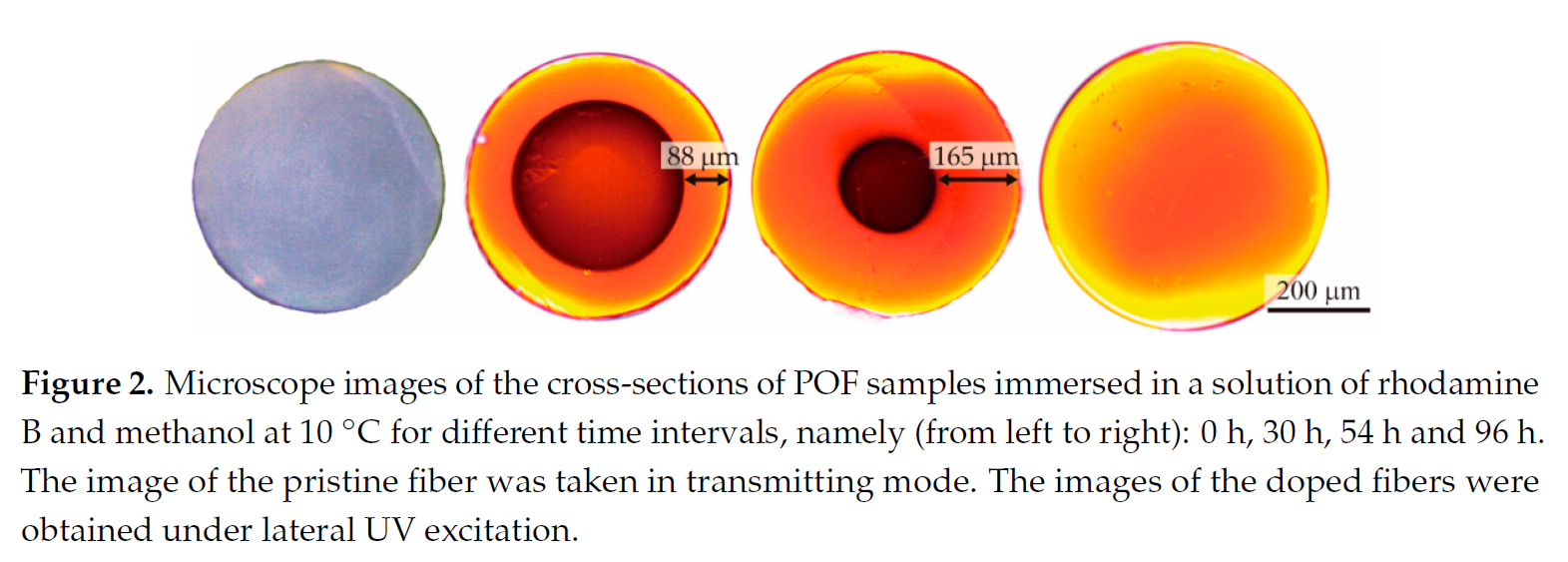

This paper employs the solution-doping technique for the fabrication of active polymer optical fibers (POFs), in which the dopant molecules are directly incorporated into the core of non-doped uncladded fibers. Firstly, we characterize the insertion of a solution of rhodamine B and methanol into the core of the fiber samples at different temperatures, and we show that better optical characteristics, especially in the attenuation coefficient, are achieved at lower temperatures. Moreover, we also analyze the dependence of the emission features of doped fibers on both the propagation distance and the excitation time. Some of these features and the corresponding ones reported in the literature for typical active POFs doped with the same dopant are quantitatively similar among them. This applies to the spectral location of the absorption and the emission bands, the spectral displacement with propagation distance, and the linear attenuation coefficient. The samples prepared in the way described in this work present higher photostability than typical samples reported in the literature, which are prepared in different ways

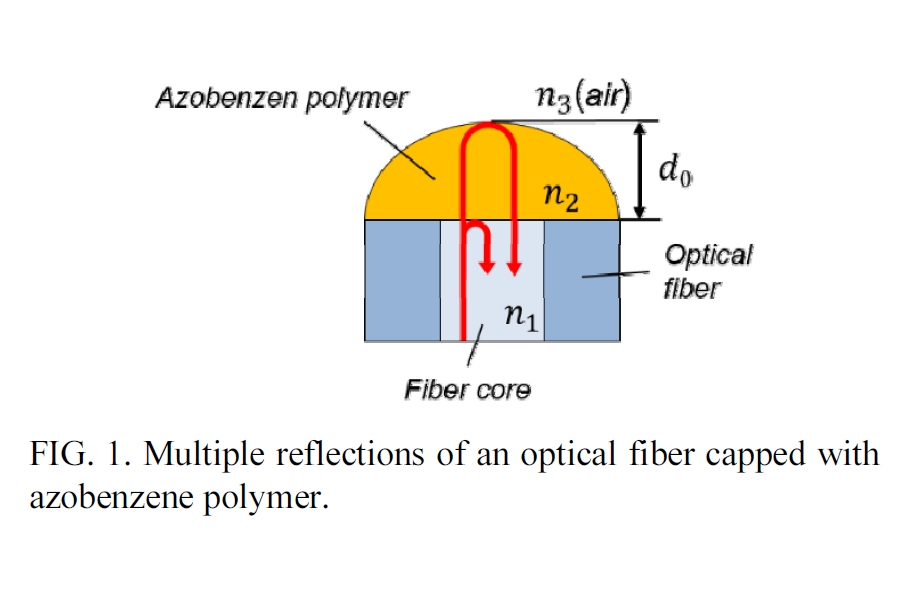

We propose a simple ultraviolet (UV) sensor consisting of a conventional single-mode optical fiber capped with an azobenzene-moiety-containing polymer. The UV light changes the dimensions of the azobenzene polymer, as well as the refractive index of the material. Incident light with a wavelength of 1550 nm was reflected at the fiber/polymer and polymer/air interfaces, and interference of the reflected beams resulted in spectral interference that shifted the wavelength by 0.78 nm at a UV input power of 2.5 mW/cm2. The UV sensor’s response to wavelength is nonlinear and stable. The response speed of the sensor is limited by detection noise, which can be improved by modifying the insertion loss of the UV sensor and the signal-to-noise ratio of the detection system. The proposed compact UV sensor is easy to fabricate, is not susceptible to electromagnetic interference, and only reacts to UV light.

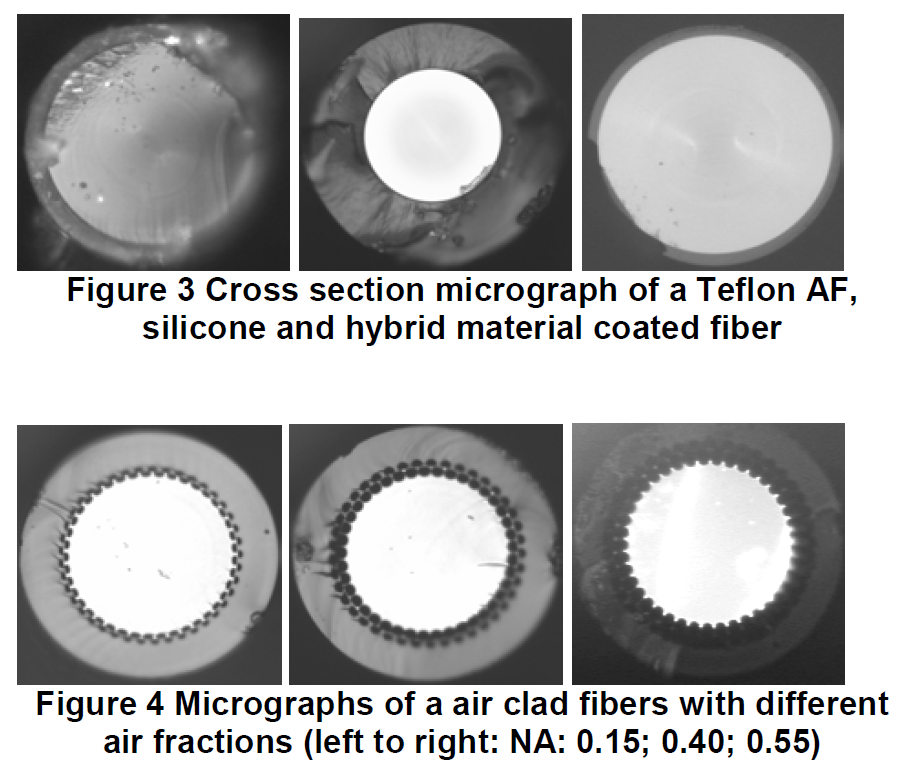

Polymer clad fibers (PCFs) represent a broad class of specialty optical fibers having numerous medical and industrial applications. Many PCFs utilize fluoroacrylate cladding materials, with or without an overcoat such as a thermoplastic or UV-curable buffer. Several harsh applications of PCFs (e.g., laser generation and high optical power transmission) require high mechanical, thermal and hydrolytic stability of the fibers. For fiber manufacturers, this has required development of new testing procedures and equipment. The article describes various kinds of PCFs and methods of their testing for different potential applications.

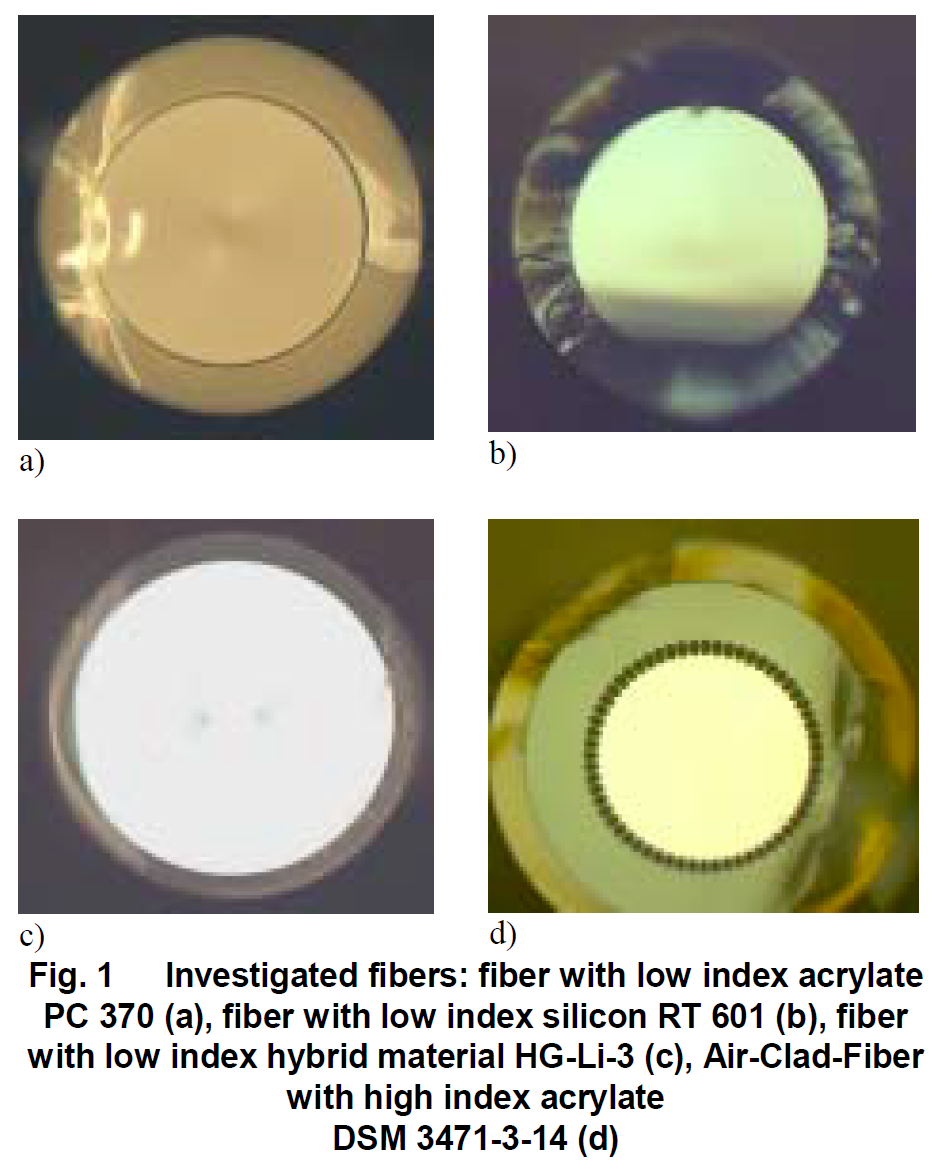

Fibers with numerical aperture of about 0.45 and higher are interesting for power transmission, remote sensing or for laser fibers with high pump efficiency. To achieve this goal we followed two ways of fiber designing. On the one hand we prepared step index

fibers with different ultra low refractive index polymer coating (fluorinated acrylate, silicon based coatings, silica based hybrid glass coatings). We investigated and reviewed thermal stability (TG) of the coatings and the optical (spectral attenuation, NA, macro-bending loss), and mechanical (tensile strength) properties of different polymer coated fibers. On the other hand microstructured optical fibers (MOF) offer new possibilities to expand the polymer material limited NA span. We fabricated different solid core air clad

MOF with maximum NA = 0.55. Despite of the obvious advantages of these holey fibers (no material absorption in air holes, high refractive index contrast 1.45:1) some specific properties have to be considered critically. The essential small bridge widths cause deficits in mechanical stability.

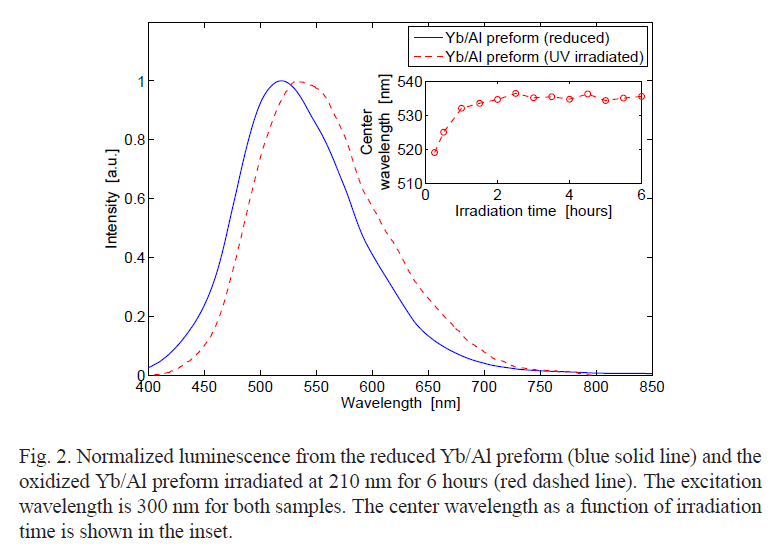

In this work we present experimental evidence that the valence instability of the ytterbium ion play a key role for the observed photodarkening mechanism in Yb-doped fiber lasers. Luminescence and excitation spectroscopy performed on UV irradiated Yb/Al doped silica glass preforms and near-infrared diode pumped photodarkened fibers show a concentration increase of Yb2+ ions. A concentration decrease in Yb3+ could also be observed for the UV irradiated preform. The findings contribute to an increased understanding of the kinetic processes related to photodarkening in Yb-doped high power fiber lasers.

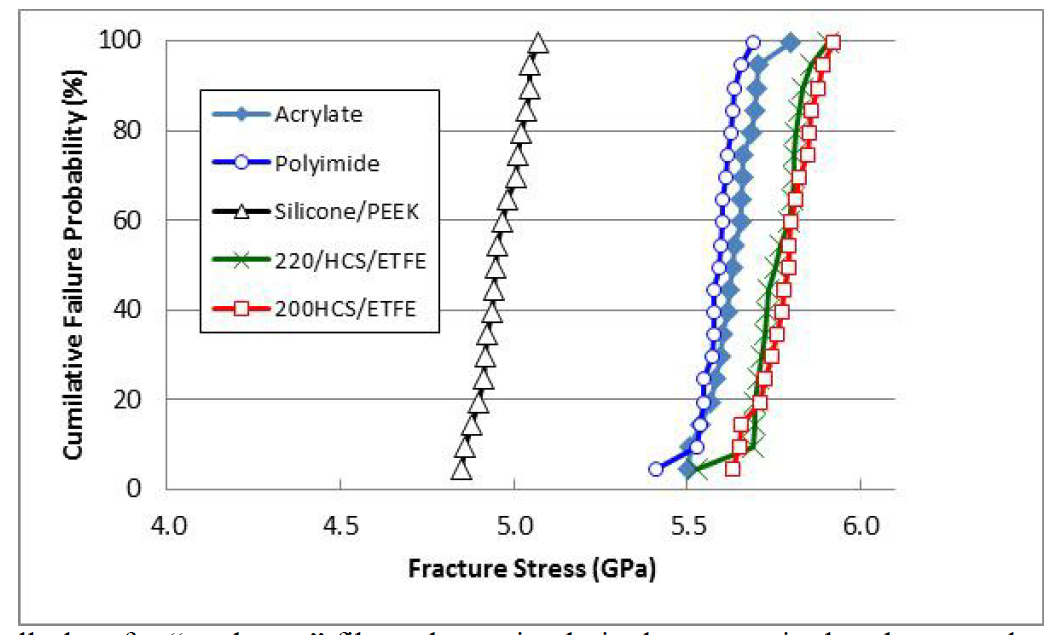

Optical fibers with different types of polymer coatings were exposed to three sterilization conditions: multiple autoclaving, treatment with ethylene oxide and treatment with gamma rays. Effects of different sterilization techniques on key optical and mechanical properties of the fibers are reported. The primary attention is given to behavior of the coatings in harsh sterilization environments. The following four coating/buffer types were investigated: (i) dual acrylate, (ii) polyimide, (iii) silicone/PEEK and (iv) fluoroacrylate hard cladding/ETFE.

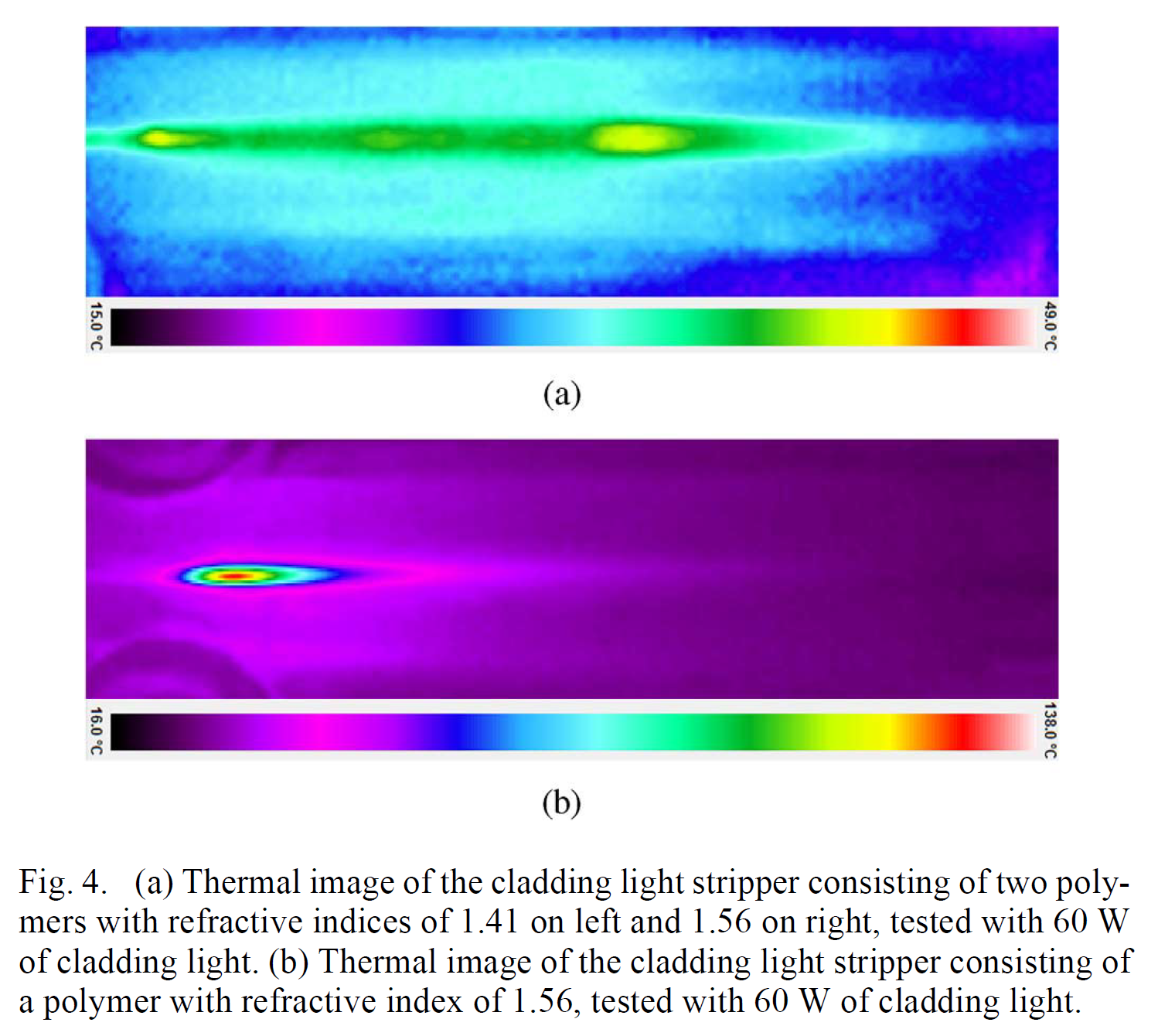

Fabrication techniques for the manufacture of a high power cladding light stripper are presented. Localized heating and thermal degradation of the recoating materials are the prime limiting factors for the operation of a high power cladding light stripper. In order to overcome this difficulty, the fiber is tapered by hydrofluoric (HF) acid and the surface of the tapered region is exposed to HF acid vapor. The acid vapor creates fine holes and scratches on the fiber surface. A low refractive index polymer is then used to recoat the fiber surface, which extracts the unwanted cladding light from the fiber over a relatively large area. This eliminates the abrupt removal of light and consequently the detrimental thermal effects due to localized heating. The power-handling capability of the device is tested under 90 W of cladding light, and attenuation of 16.7 dB is achieved

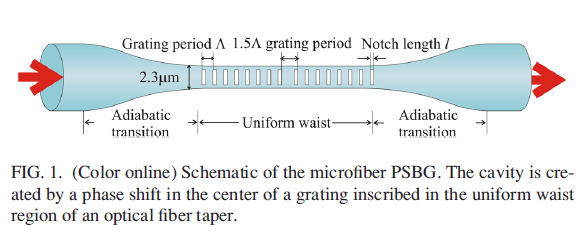

We demonstrate a type of microcavity with minimal-volume confinement using a high-contrast phase-shifted Bragg grating in a microfiber. While waveguiding by the air-silica boundary provides a diffraction-limited two-dimensional confinement, the grating introduces the third degree of confinement. Theoretical simulations verified the microfiber cavity confinement while the experimental demonstration, carried out in samples nanostructured by focused ion beam, showed a good agreement with theoretical predictions. This cavity can be used for a variety of applications ranging from sensing to quantum dynamic experiments.

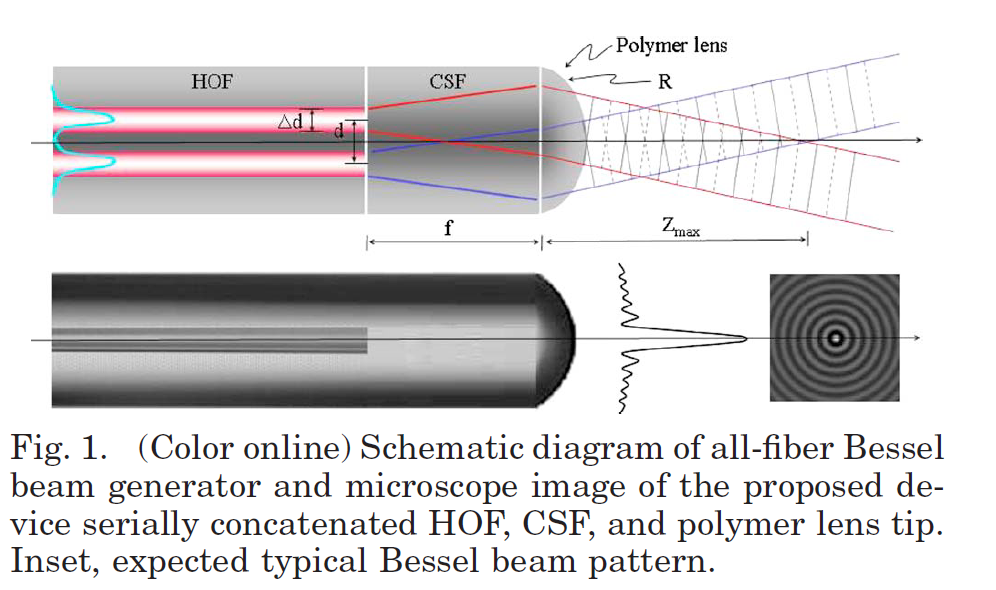

We report a compact all-fiber Bessel beam generator using hollow optical fiber (HOF) and coreless silica fiber based on a self-assembled polymer lens. A nearly diffraction-free Bessel beam pattern was observed with its focused beam diameter of 20 μm maintained over a propagation distance of 550 μm. The generated Bessel beams were experimentally tested under various structural parameters such as the diameters of the HOF and operating wavelengths. A beam propagation method was applied to simulate the proposed device, which shows good agreement with the experimental observations

The high power transmission stability is characterized by launching up to 500 W at 940 and 980 nm into the fiber over a period of at least 30 min. The most critical experimental points for comparing the stability results are the reproducible stripping of the coating with a well defined crossover and the strict clean and rectangular preparation of the fiber end faces. The far field and the numerical aperture are used as an indicator for changes of the optical coating properties. Small changes in the refractive index during the power stability tests have been detected for the low index acrylate and for the hybrid material. It was tried to correlate the results with the thermochemical investigations of the used coating materials (DTA, TG). The experimental results show the limits of applicability and the potential of both types of fibers for high power applications

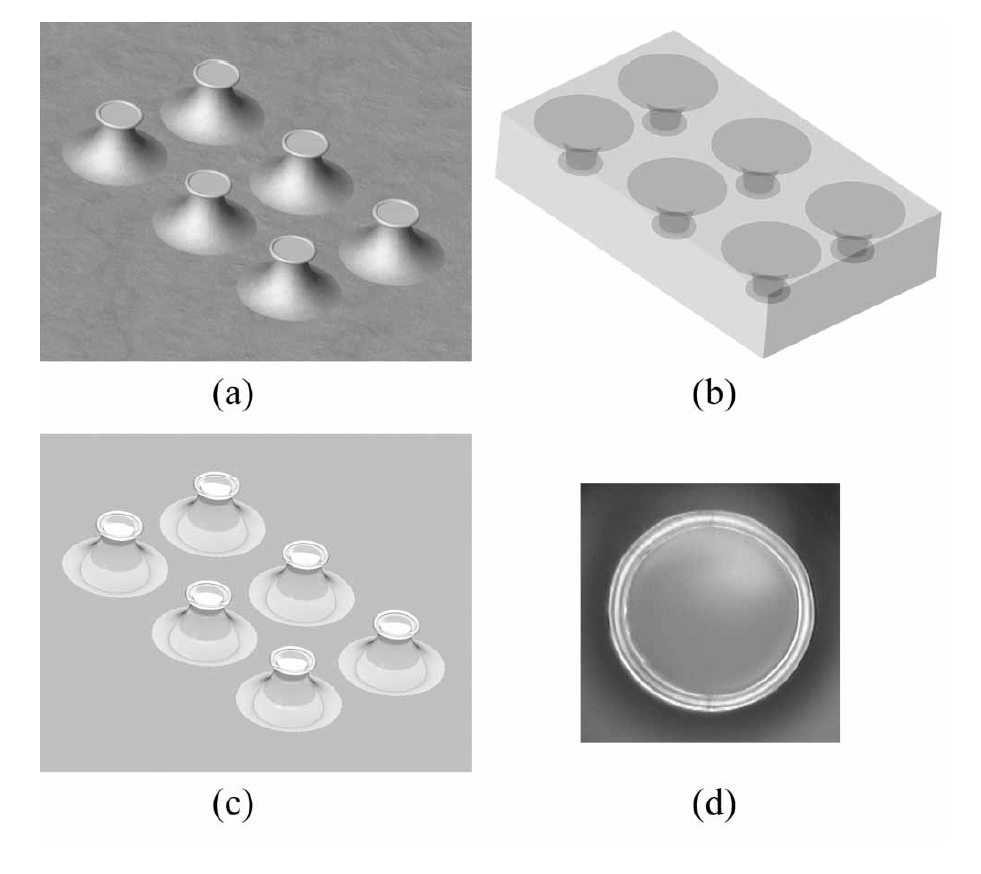

Replica molding of ultra-high-Q toroidal microresonators can produce polymer microresonators with material-limited quality factors (Q). This was demonstrated previously using polymers which cure thermally. In this work, high Q polymer microresonators were fabricated using the replica molding technique from previously uncharacterized polymers which require either a thermal or UV cure. The quality factor and effective refractive index of whispering gallery modes was measured at wavelengths ranging from the visible (680nm) through the near-IR (1550nm). The optical absorption coefficient (material absorption) of these previously uncharacterized polymers was determined from the quality factor and effective refractive index of the polymer.

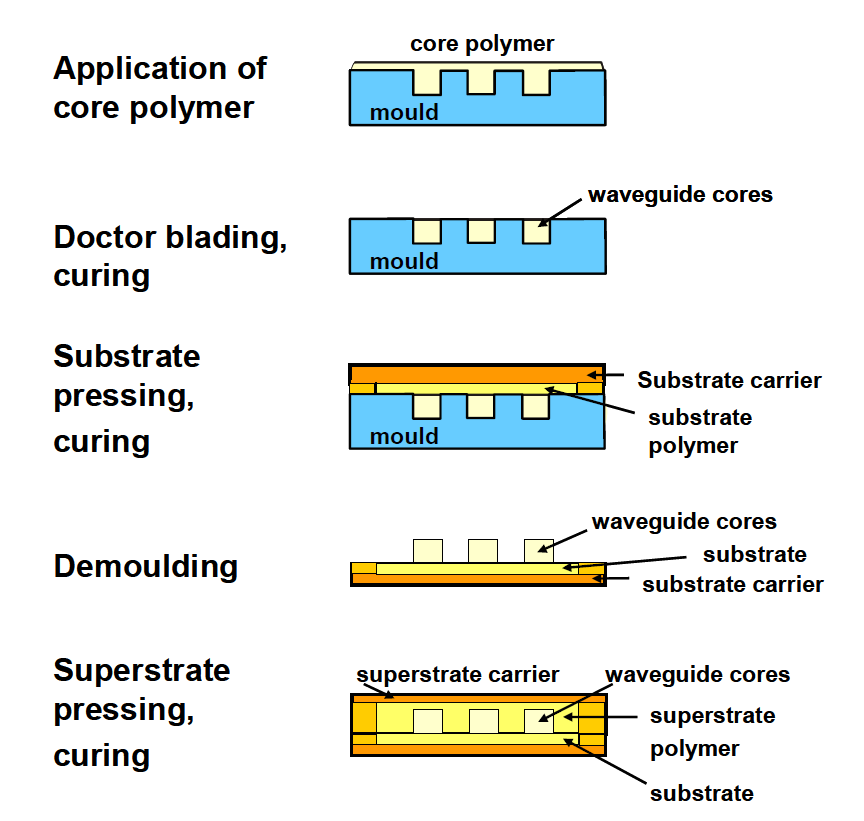

This paper reports on a new technology for the realization of an optical waveguide layer in electrical-optical circuit boards. The technology is based on casting of transparent polysiloxanes as low cost, low loss (0,05 dB/cm at 850 nm) and high temperature stable (> 250°C) material system. The waveguide layer fabrication will be discussed as well as the preparation of suitable casting moulds. Further issues are the material and waveguide properties of optical polysiloxanes, the coupling to OE-modules, and the lamination of optical layers into printed circuit boards

A Mach–Zehnder electro-optic polymer amplitude modulator is fabricated by a simple and high-throughput soft-stamp replica-molding technique. The modulator structure incorporates the highly nonlinear and stable chromophore, AJL8, doped in amorphous polycarbonate. Single-arm-phase-retardation results in a halfwave voltage sVpd of 8.4 V at 1600 nm. The on/off extinction ratio is better than 19 dB, resulting from precise Y-branch power splitters and good waveguide uniformity. These results indicate that the simple fabrication process allows for good optical performance from high-fidelity replicas of the original master devices. © 2004 American Institute of Physics. [DOI: 10.1063/1.1787944]

Technical Materials

- Polymer Clad PC Series (72 Hours PCT Passed)

- Inorganic Clad (250C High Temperature Operation)

- Optical Adhesive (High Power, High Temperature Resistance)

- Optical Fiber Coating (High Temperature Resistance)

- Display Optical Film (Lowest Refractive Index Coating)

- New Development (Holotomography, Nano-Imprint, Low Refractive Index Resin Inkjet)

The testing was performed with the water-diluted solution (organic dilution solvent) of the submitted sample, and the dilution ratio to water (organic dilution solvent) was one to one thousand. Dilution factor was not applied to the calculation of result values.

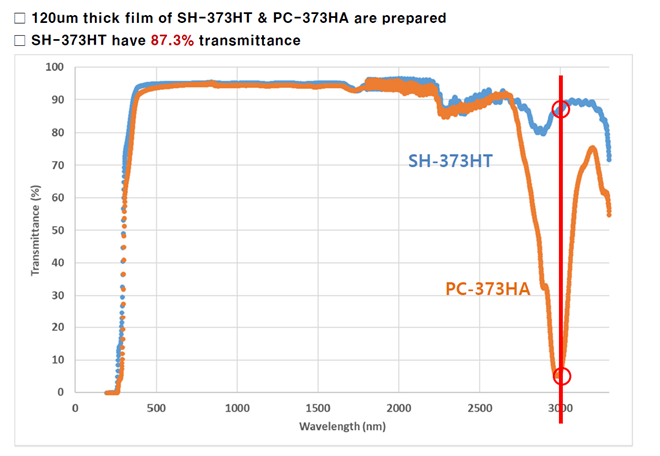

- 120um thick film of SH-373HT & PC-373HA are prepared

- SH-373HT have 87.3% transmittance

FAQ

Q How do I order low index materials on this website

Click 'STORE' on right upper corner, only sample sizes of 45g & 100g can ordered. For commercial pricing and size, please contact local representative.

Q Where can I download the full catalog

Please click recent catalog icon in Technical Materials section above or contact your local representative

Q How I can order low index materials in large volume 1000g or more

On this web-store, we offer only 45g and 100g packages size. 1000g package with volume discounts are available. Please contact a local representative in your country, or contact Luvantix ADM Co., Ltd.

Q Is TDS or more detailed specification available

TDS, SDS, and COT will be included in the package. If you need TDS before order, please contact any representative in your area, or contact Luvantix ADM Co., Ltd.

Online Inquiry

Contact Details

- Luvantix ADM Co., Ltd. (Korea)

27, Gukjegwahak 8-ro, Yuseong-gu,

Daejeon, Korea 34000

Tel: +82 42 862 0596

contact@LuvantixADM.com - Luvantix Japan (Okura Chem-Tech Corp.)

R&H Bld. 5F, 3-1-31, Edobori, Nishi-ku,

Osaka, 550-0002, Japan

Tel: +81 6 6441 0166

ozawa@okura-ct.co.jp - Luvantix Inc. (USA)

1 Pennsylvania Plaza, Suite1423,

New York, NY 10119 USA

Tel: +1 917 576 6215

contact@LuvantixUSA.com - Luvantix China (Streamway International Trading Co., Ltd.)

Unit-805, Golden Building, 108 Creative Square, No. 11 Yujinggang Road, Shanghai China 200070

Tel: +86-21-6148-8071 EXT 815 - Luvantix EU

Available for exclusive position, please contact Luvantix ADM Co., Ltd. - Luvantix India

Available for exclusive position, please contact Luvantix ADM Co., Ltd.